Cut Maintenance Costs with Drone Pipeline Inspections

More than 2.7 million miles of pipeline operate over federal ground. As pipelines are further developed, it becomes necessary to improve upon their cost-effectiveness while not sacrificing safety. New unmanned aerial vehicle (drone) technology can help. Pipelines have to be maintained to remain safe, and there are many advantages to using unmanned aerial vehicles for these tasks. Through sensors and scanners, UAVs can be used to maintain large-scale pipeline projects at minimal cost.

The Importance of Safety and Maintenance

The energy industry is required to maintain strict safety standards. There are substantial risks that are inherent to moving large volumes of volatile and hazardous materials. Though pipelines are constructed to be as reliable as possible, they can still break down over time due to high pressures of liquids and gasses. Without UAV pipeline inspections, these pipelines have to be manually inspected by aerial flight crews or ground based crews.

Traditional aerial flight crews are prohibitively expensive, which can ultimately lead to a pipeline company performing inspections less often than they should. This further increases the amount of overhead for the company, which can adversely impact how competitive and profitable the company can be. UAV pipeline inspections solve these problems, by providing fast, convenient inspection options, which improve overall reliability and safety.

The Advantages of Aerial Sensors

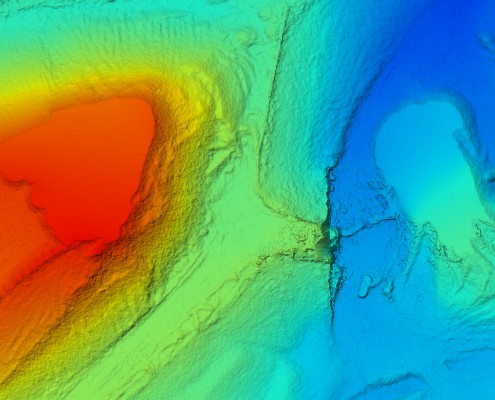

UAVs aren’t just used to perform visual inspections on pipelines. UAVs can be fitted with a number of sensors, which can be used to detect different types of pipeline damage. Some of these forms of pipeline damage wouldn’t be visible to physical inspections and therefore could not be caught by on foot inspectors. Catching these issues early on will lead to reduced costs and improved safety.

Detecting Thermal Leaks With Drones

Drones can be used to automatically sense increases in temperature surrounding the pipeline. This can reveal dangerous leaks before the leaks have been physically detected. Any leaks can then be recorded through GPS so that the leak can be located to be repaired as soon as possible.

Detecting Gas Leaks through Air Quality Detection

Thermal imaging isn’t the only way to detect gas leaks. Drones can also be fitted with sensors that are designed to detect issues with air quality. Methane and ethane can be detected through these sensors. Reports can then be generated regarding the precise location of the methane or ethane leak, so they can then be investigated by maintenance crews.

By performing these gas detection tests frequently, pipelines can reduce environmental damage and potential safety issues. Altogether, this creates a safer and more consistent work environment, as well as protecting the company’s reputation.

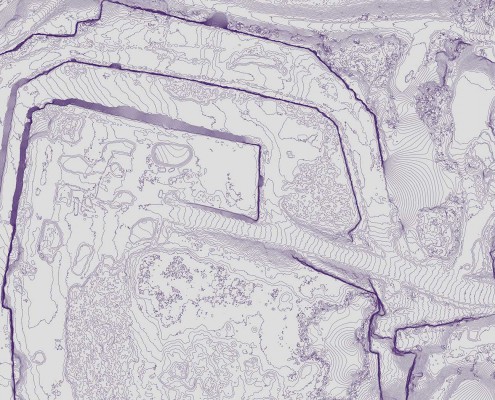

Locating the Precise Locations of Pipeline Damage

The archiving of damage data for future reference is one of the major challenges for modern pipeline maintenance. UAV pipeline inspections can be done frequently to identify any issues that have arisen before they become problems. As mentioned, the precise location of any identified damage can be reported and logged, which ensures that this type of damage isn’t missed and doesn’t become more significant over time. By making inspections faster, more effective, and more accurate, pipeline companies are better able to perform these inspections on a timely basis.

Identifying Physical Damage and Environmental Concerns

Finally, drone pipeline inspection is also able to see evidence of physical damage and environmental issues. Drones may be able to identify exposed pipelines, erosion, or the overgrowth of plant-life that could be slowly intruding upon the pipeline project. This can be done over uneven terrain, which may not be easily physically inspected.

Drones can provide extremely comprehensive UAV pipeline inspections, with a wide array of sensors and imaging. All of this can reduce the maintenance costs associated with pipeline installation and production. For more information, contact the experts at Landpoint.