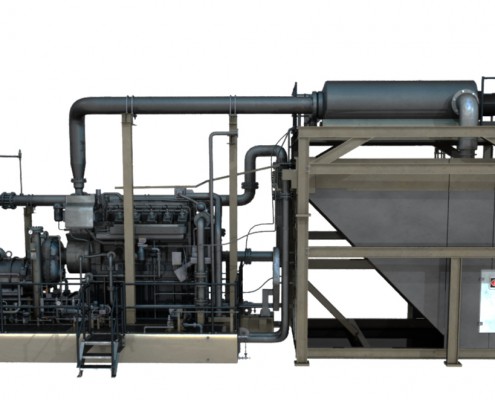

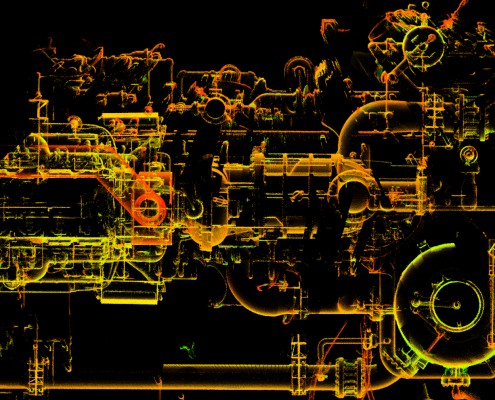

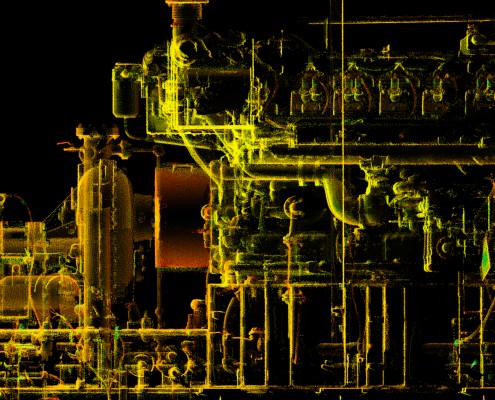

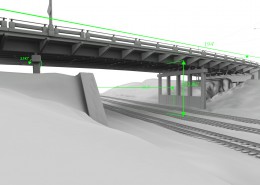

Compression Skid

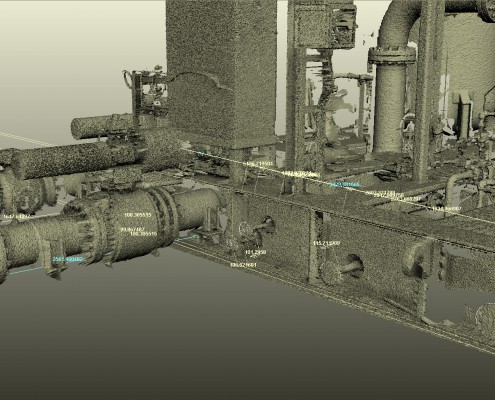

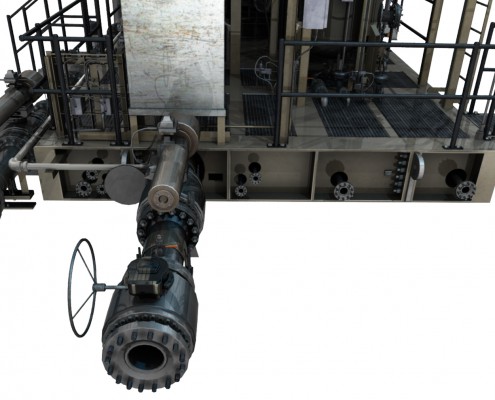

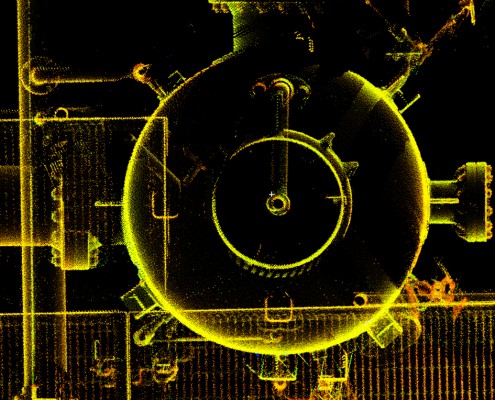

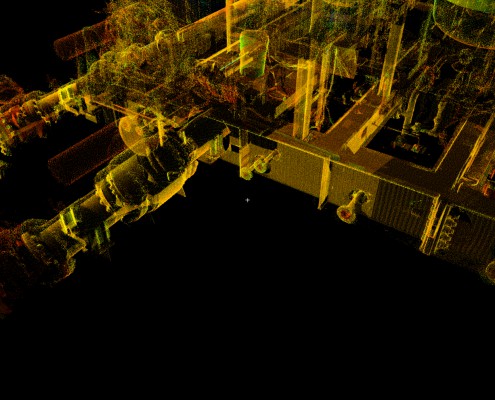

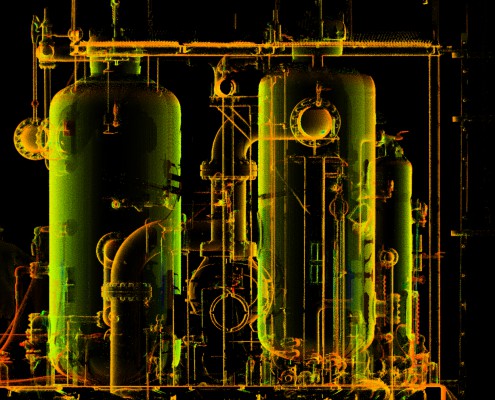

Landpoint was contracted to scan a compression skid in the final stages of assembly. Exact measurements were needed on all the connecting flanges as well as locating each center in relation to the skid’s datum. These measurements were then used to complete construction and allow piping to be pre-installed on site at the compression skid’s final destination.

In a time sensitive industry, this pre-planning allowed the unit to be operational much quicker than the conventional method which consists of waiting for the unit to arrive on site prior to building the piping.

Downloads

To download a 3D PDF and access design documents for the Skid click the button below.

Scope / Requirements

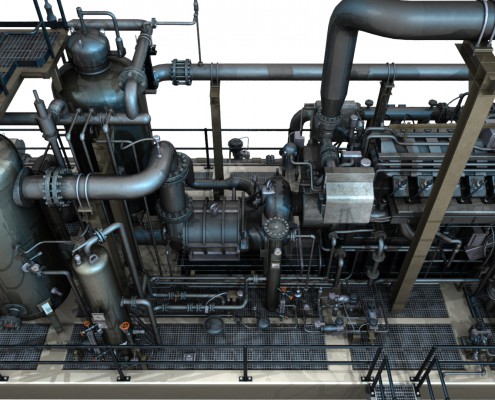

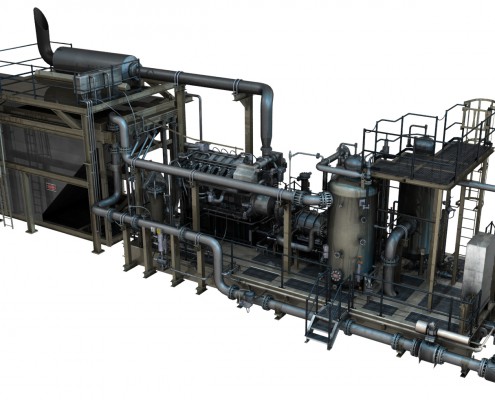

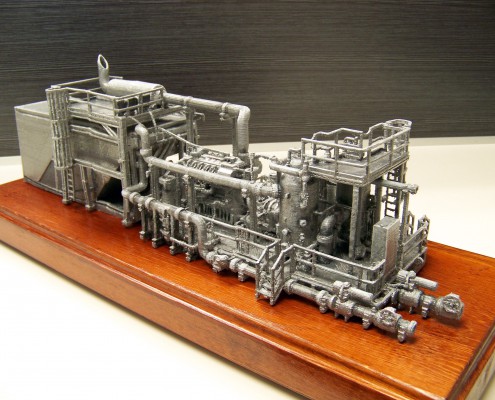

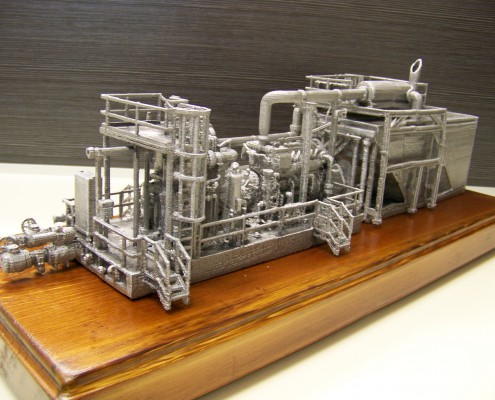

Along with collecting the measurements, a 3D model and video was created to show the functions of the skid. The 3D model was then printed in 3D and submitted to the client for training and display purposes.

Location

Houston, TX

On Site Time

7 Hours

Completion Time

- 1 Day for scanning

- 17 Days for modeling and animation

- 5 Days for deliverable production

Final Product

The location of all connections were based on datum and delivered in a 3D PDF and animation video format.

3D Model

Along with collecting the measurements, a 3D model and video was created to show the functions of the skid. The 3D model was then printed in 3D and submitted to the client for training and display purposes.s.